DIN7991 Hex Socket Countersunk Skru Ite Erogba Irin Zinc Palara Ite 8.8 10.9

DIN7991 Hex Socket Countersunk Skru Ite Erogba Irin Zinc Palara Ite 8.8 10.9

Apejuwe

YARAIdahun

YARAAsọsọ

YARAIfijiṣẹ

SETAN LATI GBE OKUN

10000+ SKU ni ile ise

A ṣe adehun fun awọn nkan RTS:

70% awọn ohun ti a firanṣẹ laarin 5 ọjọ

80% awọn ohun ti a firanṣẹ laarin 7 ọjọ

90% awọn ohun ti a firanṣẹlaarin 10 ọjọ

Awọn ibere olopobobo, jọwọ kan si iṣẹ alabara

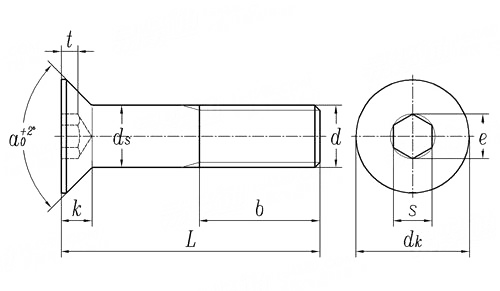

| d | M3 | M4 | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | (M18) | M20 | (M22) | M24 | |

| P | ipolowo | 0.5 | 0.7 | 0.8 | 1 | 1.25 | 1.5 | 1.75 | 2 | 2 | 2.5 | 2.5 | 2.5 | 3 |

| α | tol.(+2) | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 90° | 60° | 60° |

| b | L≤125mm | 12 | 14 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 |

| 125 L≤ 200 | / | / | / | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 56 | 60 | |

| L:200 | / | / | / | / | / | 45 | 49 | 53 | 57 | 61 | 65 | 69 | 73 | |

| dk | O pọju=Orúkọàyè | 6 | 8 | 10 | 12 | 16 | 20 | 24 | 27 | 30 | 33 | 36 | 36 | 39 |

| Min | 5.7 | 7.64 | 9.64 | 11.57 | 15.57 | 19.48 | 23.48 | 26.48 | 29.48 | 32.38 | 35.38 | 35.38 | 38.38 | |

| ds | O pọju=Orúkọàyè | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 |

| Min | 2.86 | 3.82 | 4.82 | 5.82 | 7.78 | 9.78 | 11.73 | 13.73 | 15.73 | 17.73 | 19.67 | 21.67 | 23.67 | |

| e | Min | 2.3 | 2.87 | 3.44 | 4.58 | 5.72 | 6.86 | 9.15 | 11.43 | 11.43 | 13.72 | 13.72 | 16 | 16 |

| k | O pọju | 1.7 | 2.3 | 2.8 | 3.3 | 4.4 | 5.5 | 6.5 | 7 | 7.5 | 8 | 8.5 | 13.1 | 14 |

| s | Orúkọ | 2 | 2.5 | 3 | 4 | 5 | 6 | 8 | 10 | 10 | 12 | 12 | 14 | 14 |

| Min | 2.02 | 2.52 | 3.02 | 4.02 | 5.02 | 6.02 | 8.025 | 10.025 | 10.025 | 12.032 | 12.032 | 14.032 | 14.032 | |

| O pọju | 2.1 | 2.6 | 3.1 | 4.12 | 5.14 | 6.14 | 8.175 | 10.175 | 10.175 | 12.212 | 12.212 | 14.212 | 14.212 | |

| t | O pọju=Orúkọàyè | 1.2 | 1.8 | 2.3 | 2.5 | 3.5 | 4.4 | 4.6 | 4.8 | 5.3 | 5.5 | 5.9 | 8.8 | 10.3 |

| Min | 0.95 | 1.55 | 2.05 | 2.25 | 3.2 | 4.1 | 4.3 | 4.5 | 5 | 5.2 | 5.6 | 8.44 | 9.87 | |

Apejuwe alaye

Awọn fasteners agbara giga yoo ṣe agbejade crispness nigbati galvanized. Nilo akiyesi pataki.

Imudanu hydrogen ni a maa n ṣe afihan nipasẹ idaduro idaduro labẹ wahala. Awọn orisun omi ọkọ ayọkẹlẹ ti wa, awọn fifọ, awọn skru, awọn orisun omi dì ati awọn ẹya miiran ti galvanized, ni awọn wakati diẹ lẹhin apejọ ti bajẹ, ipin fifọ ti 40% ~ 50%. Ninu ilana ti lilo awọn ẹya-palara cadmium ti ọja pataki kan, fifọ fifọ ipele kan wa, ati pe a ti yanju iṣoro bọtini orilẹ-ede kan ati pe a ṣe agbekalẹ ilana gbigbẹ ti o muna. Ni afikun, nibẹ ni o wa diẹ ninu awọn hydrogen embrittlement ko ni fi leti dida egungun lasan, gẹgẹ bi awọn: electroplating hanger (irin waya, Ejò wire) nitori ọpọlọpọ igba ti electroplating ati pickling plating, hydrogen ilaluja jẹ diẹ to ṣe pataki, igba han ni lilo a agbo yoo waye brittle fracture lasan; Awọn mandrel ti ibọn kan, lẹhin igba pupọ ti chroming, ṣubu si ilẹ ati fifọ; Diẹ ninu awọn ẹya ti a ti pa (iṣoro inu inu nla) yoo kiraki nigbati o ba yan. Awọn ẹya wọnyi jẹ hydrogenated pupọ ati kiraki laisi wahala ita, eyiti ko le ṣee lo lati mu pada lile atilẹba pada nipasẹ gbigbẹ.

Awọn ti o ga awọn ohun elo ti agbara, ti o tobi ni hydrogen embrittlement ifamọ. Eyi jẹ imọran ipilẹ ti o gbọdọ ṣe alaye nipasẹ awọn onimọ-ẹrọ itọju dada nigbati o n ṣajọ awọn pato ilana ilana itanna. Awọn irin pẹlu agbara fifẹ σb> 105kg / mm2 ti o nilo nipasẹ awọn ipele agbaye yẹ ki o wa labẹ aapọn iṣaaju-plating ati itọju dehydrogenation post-plating gẹgẹbi. Ile-iṣẹ ọkọ ofurufu Faranse nilo itọju dehydrogenation ti o baamu fun awọn ẹya irin pẹlu agbara ikore σs>90kg/mm2.

Nitori ifọrọranṣẹ ti o dara laarin agbara irin ati lile, o jẹ oye diẹ sii ati irọrun lati ṣe idajọ ifamọ ifamọ hydrogen ti ohun elo nipasẹ lile ju agbara lọ. Nitori iyaworan ọja pipe ati ilana ẹrọ yẹ ki o samisi pẹlu lile irin. Ninu ẹrọ itanna, a rii pe líle ti irin ni ayika HRC38 bẹrẹ lati ṣe afihan eewu ti fifọ embrittlement hydrogen. Fun awọn ẹya ti o ga ju HRC43, gbigbemi yẹ ki o gbero lẹhin fifin. Nigbati lile ba fẹrẹ to HRC60, itọju dehydrogenation gbọdọ ṣee ṣe lẹsẹkẹsẹ lẹhin itọju dada, bibẹẹkọ awọn ẹya irin yoo ya laarin awọn wakati diẹ.

Iṣakojọpọ

Nipa re

* Aworan ti o tẹle n ṣe idanimọ awọn incoterms iṣowo ti o yatọ. Jọwọ yan eyi ti o fẹ.

gbigbona-tita ọja

Didara Lakọkọ, Idaniloju Aabo